山东途畅路桥工程有限公司

联系人:石总

电话:18264104888

地址:山东省济南市槐荫区经一路273号群盛华城

冷再生机租赁:道路冷再生时粒径过大该怎么处理

1 总 则

1 General Provisions

1.1 冷再生是一种利于和节约能源的道路维修方式。为推广此项技术,保证冷再生设计施工质量,特制定本指南。

1.1 Cold regeneration is a road maintenance method that is beneficial for environmental protection and energy conservation. To promote this technology and ensure the quality of cold recycling design and construction, this guide is specially formulated.

1.2 本指南规定了水泥稳定就地冷再生的设计方法、设计要点及施工工艺和质量控制要求。

1.2 This guideline specifies the design methods, key points, construction techniques, and quality control requirements for on-site cold recycling of cement stabilization.

1.3 本指南适用于采用水泥稳定就地冷再生技术进行大修、改建的各等级公路的底基层和二级及二级以下公路、城市出口路基层的施工。

1.3 This guide is applicable to the construction of sub base layers and sub base layers of various grades of highways, as well as urban exit road bases, that undergo major repairs and renovations using cement stabilized in-situ cold recycling technology.

1.4 本指南中的规定、要求与《辽宁省“十一五”公路技术政策(试行)》中相应内容不一致时,以本指南为准。

In case of any inconsistency between the provisions and requirements in this guide and the corresponding content in the "Eleventh Five Year Plan" Highway Technology Policy (Trial) of Liaoning Province, this guide shall prevail.

1.5 水泥稳定就地冷再生路面设计应采用设计与施工紧密结合的半刚性基层设计理论,设计内容包括交通量预测与分析、旧路混合料分析、混合料配合比设计、设计参数确定、路面结构组合设计与厚度计算,在进行路面结构技术经济综合评价的基础上提出设计方案。

The design of 1.5 cement stabilized in-situ cold recycled pavement should adopt a semi-rigid base design theory that closely combines design and construction. The design content includes traffic volume prediction and analysis, analysis of old road mixtures, mix design, determination of design parameters, pavement structure combination design and thickness calculation. Based on the comprehensive evaluation of pavement structure technology and economy, a design scheme should be proposed.

1.6 就地冷再生机的再生深度一般为15cm -30cm。损坏深度大于30cm或需要提高或改善路面使用功能时,采用水泥稳定就地冷再生基层后,应加铺满足设计强度的半刚性上基层,路面结构按《公路沥青路面设计规范》有关规定,通过交通量预测计算设计弯沉值后,进行路面结构厚度计算,并进行弯拉应力验算。

The regeneration depth of the on-site cold regeneration machine is generally 15cm -30cm. When the depth of damage is greater than 30cm or when it is necessary to improve or enhance the functionality of the road surface, after using cement stabilized on-site cold recycled base layer, a semi-rigid upper base layer that meets the design strength should be added. The road surface structure should be designed according to the relevant provisions of the "Design Specification for Asphalt Pavement of Highways". After calculating the design deflection value through traffic volume prediction, the thickness of the road surface structure should be calculated, and the bending tensile stress should be verified.

1.7 本指南涉及的试验方法应符合现行有关试验规程的规定。

1.7 The test methods involved in this guideline shall comply with the current relevant test regulations.

1.8 再生前必须进行路况调查,确定路面损坏是于路面面层,还是属于路面结构问题,了解路面结构损坏的范围和深度。

Before regeneration, a road condition survey must be conducted to determine whether the road damage is limited to the surface layer or a structural issue, and to understand the scope and depth of the road structure damage.

1.9 再生施工中除进行路面混合料级配检测外,应避免预破碎,在必须采用预破碎的路段,应严格控制铣刨深度。

In addition to conducting gradation testing on road mixtures during the 1.9 recycling construction, pre crushing should be avoided. In sections where pre crushing is necessary, the milling depth should be strictly controlled.

1.10 进行室内材料配合比设计所需混合料原则上应用再生机进行现场取料(即旧路混合料)。不同结构路段应独立进行结构组合设计和混合料配合比设计。

The required mixture for indoor material mix design should generally be collected on-site using a recycling machine (i.e. old road mixture). Different structural sections should be independently designed for structural combinations and mix proportions.

1.11 就地再生设备应能精确控制再生深度,误差不宜超过10mm;应能根据要求调整横坡,适当调整再生料的级配;应能控制添加料的比例并根据需要自动调节。

1.11 The on-site regeneration equipment should be able to accurately control the regeneration depth, with an error not exceeding 10mm; it should be able to adjust the cross slope according to requirements and adjust the grading of the regenerated material appropriately; Should be able to control the proportion of additives and automatically adjust as needed.

1.12 下列情况原则上不宜采用就地水泥稳定就地冷再生技术:

1.12 In principle, on-site cement stabilization and on-site cold recycling technology should not be used in the following situations:

(1)在预估的再生深度范围内,存在过多超粒径颗粒(粒径超过10cm的砂砾或铁渣等),会对铣刨转子造成损害的道路;

(1) Within the estimated regeneration depth range, there are too many oversized particles (such as gravel or iron slag with a maximum particle size exceeding 10cm) that can cause damage to the milling rotor on the road;

(2)病害较多,变形严重,强度不足的道路;

(2) Roads with multiple diseases, severe deformation, and insufficient strength;

(3)旧路结构层总厚度(面层、基层及垫层之和)小于25cm的道路。

(3) Roads with a total thickness of less than 25cm for the structural layer of the old road (the sum of the surface layer, base layer, and cushion layer).

1.13 沥青路面面层厚度不大于7cm可采用水泥稳定就地冷再生,面层厚度大于7cm 宜在水泥稳定就地冷再生和泡沫沥青稳定就地冷再生两个方案之间进行技术经济比较后确定。

1.13 Cement stabilized in-situ cold recycling can be used for asphalt pavement with a thickness of no more than 7cm. For pavement with a thickness of more than 7cm, it should be determined after technical and economic comparison between cement stabilized in-situ cold recycling and foam asphalt stabilized in-situ cold recycling.

1.14 施工中应认真整理相关资料,不断总结施工方法和实践经验,以提高冷再生施工技术水平,并为本指南的修订提供真实可靠的实践依据。

During construction, relevant materials should be carefully organized, and construction methods and practical experience should be continuously summarized to improve the level of cold recycling construction technology and provide real and reliable practical basis for the revision of this guide.

2 术 语

2 Terminology

2.1 冷再生技术(Cold recycling)

2.1 Cold Recycling Technology

将需要改建或大修的旧路面,经过翻挖回收、破碎、筛分,并加入适量的稳定剂(水泥、乳化沥青、泡沫沥青等),在常温情况下重新拌和,形成具有一定路用性能的再生混合料,用于铺筑路面基层或底基层的整套工艺技术。

The old pavement to be reconstructed or overhauled shall be excavated, recycled, crushed, screened, and added with a proper amount of stabilizer (cement, emulsified asphalt, foam asphalt, etc.), and remixed at normal temperature to form a recycled mixture with certain road performance, which is used for the whole process technology of paving the pavement base or subbase.

2.2 旧混合料(Recycled mixtures)

2.2 Recycled mixtures

对需要再生的道路按规定要求进行整形处理,经再生机(或铣刨机)按规定的深度、行进速度和转子速度进行铣刨后得到的具有一定级配的混合料。

The mixture with a certain gradation is obtained by shaping the road that needs to be regenerated according to the prescribed requirements, and milling it with a recycling machine (or milling machine) according to the prescribed depth, travel speed, and rotor speed.

2.3 水泥稳定就地冷再生(Cold recycling with cement as stabilizing agent)

2.3 Cold recycling with cement as stabilizing agent

在旧混合料(必要时加入一定比例的新料)中,加入一定剂量的水泥,在含水量状态下拌和形成再生混合料,通过整形、碾压、养生形成符合设计要求的道路基层或底基层。

In the old mixture (with a certain proportion of new material added if necessary), a certain amount of cement is added and mixed at the optimal moisture content to form a recycled mixture. Through shaping, rolling, and curing, a road base or subbase that meets the design requirements is formed.

2.4 再生深度(Recycling depth)

2.4 Recycling depth

再生机设定的铣刨深度,一般指原道路标高与再生层底部标高之差。

The milling depth set by the regeneration machine generally refers to the difference between the original road elevation and the bottom elevation of the regeneration layer.

2.5 再生厚度(Recycling thickness)

2.5 Recycling thickness

再生层设计顶面标高与底面标高之差,指再生层碾压成型后的顶面标高与底面标高之差。

The difference between the top and bottom elevations of the recycled layer design refers to the difference between the top and bottom elevations of the recycled layer after rolling and forming.

2.6 均匀路段(Homogeneous road section)

2.6 Homogeneous Road Section

旧路中结构组成及各结构层材料相同或相似并且具有相似结构承载力的路段。

The old road section has the same or similar structural composition and materials of each structural layer, and has similar structural bearing capacity.

3 一般规定

3 General Provisions

3.1 水泥稳定就地冷再生混合料用做基层或底基层时,水泥剂量可采用4%-5%,一般不宜超过5.5%。

When using cement stabilized in-situ cold recycled mixture as base or subbase, the cement dosage can be 4% -5%, and generally should not exceed 5.5%.

3.2 水泥稳定就地冷再生结构层宜在春末和气温较高季节组织施工。施工期的日气温应在5℃以上,在有冰冻的地区,并应在次重冰冻(-3~-5℃)到来之前半个月到一个月完成。

3.2 Cement stabilized in-situ cold recycling structural layer should be constructed in late spring and high temperature seasons. The daily minimum temperature during the construction period should be above 5 ℃, in areas with freezing, and should be completed half a month to a month before the first heavy freezing (-3~-5 ℃) arrives.

3.3 在雨季施工时,应特别注意气候变化,勿使水泥和混合料遭雨淋。降雨时应停止施工,已经摊铺的水泥混合料应尽快碾压密实。

3.3 During rainy season construction, special attention should be paid to climate change to prevent cement and mixtures from being exposed to rain. Construction should be stopped during rainfall, and the already spread cement mixture should be compacted as soon as possible.

3.4 水泥稳定就地冷再生结构层施工时,应遵守下列规定:

When constructing the cement stabilized in-situ cold recycling structural layer, the following regulations should be followed:

(1) 添加的碎石等外掺料和水泥应撒布均匀。

(1) The added crushed stone and other additives, as well as cement, should be evenly spread.

(2) 应严格控制基层厚度和高程,其路拱横坡应与面层基本一致。

(2) The thickness and elevation of the base layer should be strictly controlled, and the cross slope of the road arch should be basically consistent with the surface layer.

(3) 应在混合料处于或略大于含水量(气候炎热干燥时,基层混合料可大1%~2%)时进行碾压,压实度应达到《公路路面基层施工技术规范》(JTJ 034-2000)的有关要求。当使用大吨位压路机时,压实度宜提高1%~2%。

(3) Rolling should be carried out when the mixture is at or slightly above the optimal moisture content (when the climate is hot and dry, the base layer mixture can be 1% to 2% higher), and the compaction degree should meet the relevant requirements of the "Technical Specification for Construction of Highway Pavement Base Layer" (JTJ 034-2000). When using a large tonnage roller, the compaction degree should be increased by 1% to 2%.

(4) 水泥稳定就地冷再生结构层宜采用18t以上的振动压路机碾压。压实厚度15-20cm,采用18~20t振动压路机碾压;超过20 cm以上压实厚度应采用25t以上振动压路机。冷再生结构层碾压工序应在水泥初凝前完成。

(4) The cement stabilized in-situ cold recycling structural layer should be compacted with a vibratory roller weighing at least 18 tons. The compaction thickness is 15-20cm, and a 18-20t vibratory roller is used for rolling; For compaction thickness exceeding 20 cm, a vibratory roller with a capacity of 25 tons or more should be used. The rolling process of the cold recycled structural layer should be completed before the initial setting of the cement.

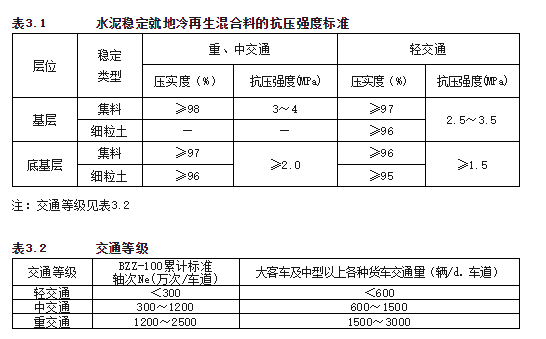

3.5 各级公路用水泥稳定就地冷再生混合料的压实度、7d龄期无侧限抗压强度应符合表3.1的规定。

The compaction degree and 7-day unconfined compressive strength of cement stabilized in-situ cold recycled mixtures used for highways at all levels shall comply with the provisions of Table 3.1.

3.6 水泥稳定就地冷再生混合料的组成设计应根据表3.1的强度标准,通过试验确定必需的水泥剂量和混合料的含水量,在需要改善混合料的物理力学性质或级配时,还应确定掺加新料的规格和比例。

3.6 The composition design of cement stabilized in-situ cold recycled mixture should be based on the strength standards in Table 3.1, and the necessary cement dosage and optimal moisture content of the mixture should be determined through experiments. When it is necessary to improve the physical and mechanical properties or gradation of the mixture, the specifications and proportions of adding new materials should also be determined.

3.7 水泥稳定就地冷再生的各项试验应按《公路工程无机结合料稳定材料试验规程》(JTJ057)进行。

The various tests for on-site cold recycling of cement stabilization should be conducted in accordance with the "Test Code for Inorganic Bonding Materials in Highway Engineering" (JTJ057).

表3.1 水泥稳定就地冷再生混合料的抗压强度标准

Table 3.1 Compressive Strength Standards for Cement Stabilized In situ Cold Recycled Mixtures

4 路况调查

4 Road condition investigation

4.1 收集查阅相关资料

4.1 Collect and review relevant materials

(1) 原路面设计情况以及路面设计的任何变化;

(1) The original pavement design and any changes in pavement design;

(2) 路面各结构层厚度及材料的详细情况;

(2) Detailed information on the thickness and materials of each structural layer on the road surface;

(3) 施工记录的施工工艺和质检测试结果;

(3) Construction process and quality inspection test results recorded in the construction records;

(4) 路面使用过程中维修养护的详细情况(包括工艺、材料等);

(4) Detailed information on maintenance and upkeep during the use of road surfaces (including processes, materials, etc.);

(5) 历史交通量资料。

(5) Historical traffic volume data.

4.2 划分均匀路段

4.2 Division of Uniform Road Sections

4.2.1 通过获取的历史资料初步判定原道路的均匀路段,道路结构组合相差较大或结构层材料相差较大的路段不宜作为一个均匀路段。

4.2.1 Based on the obtained historical data, it is preliminarily determined that the original road section is uniform. Road sections with significant differences in road structure combinations or structural layer materials should not be considered as uniform sections.

4.2.2 对原道路进行弯沉测量,根据累积总和法初步确定均匀路段。

4.2.2 Conduct deflection measurement on the original road and preliminarily determine the uniform road section based on the cumulative sum method.

较大弯沉值(即两轮读数中的较大值)的累积总和法采用公式4.1计算:

The cumulative sum method of larger deflection values (i.e. the larger of the two readings) is calculated using formula 4.1:

(4.1)

(4.1)

——i点的累积弯沉总和值

——Accumulated total deflection of point i

——i点的较大弯沉值

——The larger deflection value of point i

——整个路段较大弯沉的平均值

——The average value of significant deflection for the entire road section

——i点前一点的累积弯沉总和值(i=1时,其值为0)

——The cumulative total deflection of the point before point i (when i=1, its value is 0)

将累积总和值绘制在相应路段上,相对恒定的斜坡值表明这些路段具有相似的路面反应。示例见图4.1(图中弯沉值单位为0.01mm)。

Plot the cumulative total value on the corresponding road sections, where relatively constant slope values indicate similar road surface responses. See Figure 4.1 for an example (the deflection value in the figure is in 0.01mm).

4.2.3 视觉评价

4.2.3 Visual evaluation

1. 视觉评价通常徒步进行。对于较长的路段,可采用慢速驾车完成评价。当驾车时,为了近距离仔细观察,需要经常停车。

Visual evaluation is usually conducted on foot. For longer road sections, slow driving can be used to complete the evaluation. When driving, frequent parking is necessary for close observation.

2. 视觉评价时,要记录整幅路面内所有明显的损坏以及其它观测结果,诸如排水、地质变化以及路段几何特征(比如陡坡、急转弯以及高填方路堤)。

When conducting visual evaluation, it is necessary to record all obvious damages and other observation results within the entire road surface, such as drainage, geological changes, and geometric features of the road section (such as steep slopes, sharp turns, and high fill embankments).

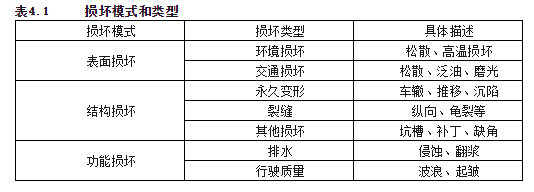

3. 检查过程中,损坏模式分为三类,表面损坏、结构损坏、功能损坏,各种损坏模式、损坏类型及具体描述见表4.1。在视觉调查中,依据损坏严重程度、频率和位置,对道路损坏的不同模式和类型进行具体描述。

During the inspection process, the damage modes are divided into three categories: surface damage, structural damage, and functional damage. The various damage modes, types, and specific descriptions are shown in Table 4.1. In visual surveys, different patterns and types of road damage are described in detail based on the severity, frequency, and location of the damage.

表4.1 损坏模式和类型

Table 4.1 Damage Modes and Types

4. 对视觉调查资料进行总结,明确路面的破坏模式,为道路损坏的原因提供有价值的线索。

4. Summarize the visual survey data, clarify the damage mode of the road surface, and provide valuable clues for the causes of road damage.

4.4 均匀路段的再评估

4.4 Re evaluation of Uniform Road Sections

结合视觉调查中获取的资料,以及所有其他可能的相关资料对由弯沉分析限定的“均匀路段”进行再次评价,以更加精确地描述各类均匀路段,更精确地对相似的“相同路段”进行识别和归类。

Based on the data obtained from visual surveys and all other possible relevant information, re evaluate the "uniform road sections" defined by deflection analysis to more accurately describe various types of uniform road sections and more accurately identify and classify similar "same road sections".

4.5 详细调查

4.5 Detailed Investigation

对每一相似的“均匀路段”,需要进行详细调查,以便对原路面结构进行评价(组成与损坏模式),确定旧路地基承载力。

For each similar 'uniform road section', a detailed investigation is required to evaluate the original pavement structure (composition and damage mode) and determine the bearing capacity of the old road foundation.

4.5.1 开挖测试坑

4.5.1 Excavation of Test Pit

1. 对每一均匀路段,测试坑每每车道应不少于一个。通常在车道外侧轮迹带开挖,也可在硬路肩(或路缘带)与行车道的交界线处开挖。

For each uniform road section, there should be no less than one test pit per kilometer per lane. Excavation is usually carried out on the outer side of the lane's wheelbase, but can also be done at the boundary between the hard shoulder (or curb) and the lane.

2. 测试坑用于确定旧路各结构层厚度和材料、现场含水量、各结构层的性状(如开裂程度、水泥稳定层的水泥粘结度或碳酸化程度)等旧路基本信息。

2. Test pits are used to determine basic information about the old road, such as the thickness and materials of each structural layer, on-site moisture content, and the characteristics of each structural layer (such as cracking degree, cement bonding degree or carbonation degree of cement stabilized layer).

3. 测试坑通常长1.2m、宽1m、深0.5-1m,具体尺寸可根据道路结构进行调整。

3. The test pit is usually 1.2m long, 1m wide, and 0.5-1m deep, and the specific size can be adjusted according to the road structure.

4. 测试坑需仔细开挖,每层材料应分开堆放,以便取样。样品应放置在密封的容器内,用于测定含水量。测试坑开挖完毕,应拍照并详细记录测试坑的路面轮廓。

4. The test pit needs to be carefully excavated, and each layer of material should be stacked separately for sampling. The sample should be placed in a sealed container for measuring moisture content. After the excavation of the test pit is completed, photos should be taken and the road surface contour of the test pit should be recorded in detail.

4.5.2 现场承载板试验

4.5.2 On site bearing plate test

1. 现场承载板试验宜选在一年中的不利季节进行。测点位置与测试坑相同,也可在试验的基础上两者同步进行。

1. The on-site bearing plate test should be conducted during the most unfavorable season of the year. The location of the measuring point is the same as that of the testing pit, and the two can also be synchronized based on the experiment.

2. 对每一均匀路段,每车道应不少于两个测点,同一均匀路段中若某一测点的数值高于(或低于)平均值的30%,应增加测点数量,同时对数值过低点附近的路段应仔细调查,看是否存在路基沉陷等下部结构层损坏问题。

2. For each uniform road section, each lane should have no less than two measuring points. If the value of a measuring point in the same uniform road section is higher (or lower) than 30% of the average value, the number of measuring points should be increased. At the same time, the road section near the low point of the value should be carefully investigated to see if there are any problems such as roadbed subsidence or damage to the lower structural layer.

3. 将道路面层认真去除,测定其下部结构层复合回弹模量。同理将道路基层、垫层完全去除,测定其下部结构层复合回弹模量,直模量测定点处的结构层深度大于预估的可能铣刨深度。

3. Carefully remove the road surface layer and measure the composite rebound modulus of its lower structural layer. Similarly, completely remove the road base and cushion layer, and measure the composite rebound modulus of the lower structural layer until the depth of the structural layer at the modulus measurement point is greater than the estimated maximum possible milling depth.

4.6 综合资料,初步确定再生厚度

4.6 Comprehensive data, preliminary determination of regeneration thickness

综合分析以上获得的信息,推测该路面的剩余使用寿命,并识别出承载力的关键层,在明确已经损坏结构层的基础上初步确定再生层的厚度。

Based on the comprehensive analysis of the information obtained above, the remaining service life of the road surface is speculated, and the key layer with the lowest bearing capacity is identified. On the basis of clarifying the damaged structural layer, the thickness of the regeneration layer is preliminarily determined.

5 结构组合设计

5. Structural combination design

5.1 旧路大修、改建时,应根据收集调查的交通量数据,确定交通量增长率,计算设计年限内一个车道的累计当量轴次,结合路面等级及路面类型,采用沥青路面半刚性设计理论,计算设计弯沉值。

During the major repair and reconstruction of old roads, the traffic growth rate should be determined based on the collected and surveyed traffic volume data, and the cumulative equivalent number of axles for one lane within the design period should be calculated. Combined with the pavement grade and type, the semi-rigid design theory of asphalt pavement should be adopted to calculate the design deflection value.

5.2 初步确定的道路结构组合方案。根据原路面设计强度和路况调查中得到的路面损坏情况,预估冷再生结构层厚度,并挖验检测冷再生结构层下承层的当量回弹模量,试算后确定再生层的厚度,一般厚度不宜小于18cm。

5.2 Preliminary determined road structure combination plan. Based on the original pavement design strength and road condition investigation, the thickness of the cold recycled structural layer is estimated, and the equivalent rebound modulus of the underlying layer of the cold recycled structural layer is excavated and tested. After trial calculation, the thickness of the recycled layer is determined, and generally the thickness should not be less than 18cm.

5.3 由路况调查中现场承载板试验获得的原路各层下部复合模量,采用内插法确定预估的道路铣刨深度处下层复合模量,以此模量作为再生层底部模量。见图5.1。

5.3 The composite modulus of the lower layer of the original road obtained from the on-site bearing plate test in the road condition survey is used to determine the estimated composite modulus of the lower layer at the milling depth of the road using interpolation method, and this modulus is used as the modulus of the bottom of the regeneration layer. Refer to Figure 5.1.

5.4 水泥稳定就地冷再生层设计参数应以实测值为准,当缺乏条件无法取得实测值时,可参照下述值进行取值。水泥剂量为4%~5.5%时,抗压模量E值为1000~1500MPa,劈裂强度为0.4~0.6MPa。

5.4 The design parameters of the cement stabilized in-situ cold regeneration layer should be based on the measured values. When there is a lack of conditions to obtain the measured values, the following values can be used for reference. When the cement dosage is 4%~5.5%, the compressive modulus E value is 1000~1500MPa, and the splitting strength is 0.4~0.6MPa.

5.5 按设计弯沉值验算结构层厚度。见示意图5.1。

5.5 Verify the thickness of the structural layer according to the design deflection value. Refer to schematic diagram 5.1.

5.6 验算结果符合要求则进行下述步骤,如验算结果不符合要求,则重新拟定结构层组成进行计算,直验算结果满足要求为止。

If the verification result meets the requirements, the following steps shall be taken. If the verification result does not meet the requirements, the structural layer composition shall be re formulated for calculation until the verification result meets the requirements.

5.7 进行技术经济比较,终确定采用的路面结构方案。

5.7 Conduct technical and economic comparisons to ultimately determine the pavement structure scheme to be adopted.

5.1 内插法确定再生层底部模量

5.1 Interpolation method to determine the modulus of the bottom of the regeneration layer

6 混合料组成设计

6. Composition design of mixed materials

6.1 材 料

6.1 Materials

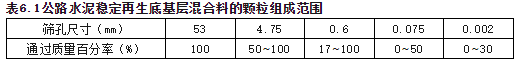

6.1.1 水泥稳定就地冷再生层用做底基层时,铣刨料单个颗粒的粒径不应超过53mm,其颗粒组成应在表6.1所列范围内。铣刨料的塑性指数不应超过10。塑性指数大于10的铣刨旧料,宜采用水泥和石灰综合稳定。

When the cement stabilized in-situ cold recycled layer is used as the base layer, the maximum particle size of a single milling material particle should not exceed 53mm, and its particle composition should be within the range listed in Table 6.1. The plasticity index of milling material should not exceed 10. Milling old materials with a plasticity index greater than 10 should be stabilized with a combination of cement and lime.

表6.1公路水泥稳定再生底基层混合料的颗粒组成范围

Table 6.1 Particle Composition Range of Cement Stabilized Recycled Subbase Mixture for Highways

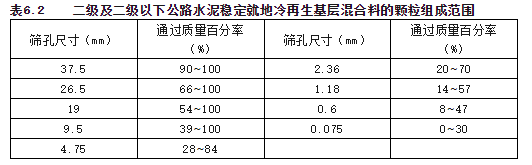

6.1.2 水泥稳定就地冷再生层用做基层时,单个颗粒的粒径不应超过37.5mm,其颗粒组成应在表6.2范围内。对于二级公路宜按接近级配范围的下限组配混合料。

When the cement stabilized in-situ cold recycled layer is used as the base layer, the maximum particle size of a single particle should not exceed 37.5mm, and its particle composition should be within the range of Table 6.2. For second-class highway, it is better to mix the mixture according to the lower limit close to the grading range.

6.1.3 原道路为沥青混合料、级配碎石、未筛分碎石、砂砾、碎石土、砂砾土、煤矸石和各种粒状矿渣均适宜用水泥稳定就地冷再生。

6.1.3 The original road is made of asphalt mixture, graded crushed stone, unscreened crushed stone, gravel, crushed stone soil, gravel soil, coal gangue, and various granular slag, all of which are suitable for on-site cold recycling stabilized with cement.

6.1.4 在水泥稳定就地冷再生层施工前,在原道路上取有代表性的铣刨料样品严格按照相关规范和规程进行下列试验:

6.1.4 Before the construction of the cement stabilized in-situ cold recycling layer, representative milling material samples shall be taken from the original road and subjected to the following tests in strict accordance with relevant specifications and regulations:

(1)颗粒分析;

(1) Particle analysis;

(2)液限和塑性指数;

(2) Liquid limit and plasticity index;

(3)击实试验;

(3) Compaction test;

(4)有机质含量(必要时做);

(4) Organic matter content (if necessary);

(5)硫酸盐含量(必要时做)。

(5) Sulfate content (if necessary).

6.1.5 对级配不良的铣刨旧料,应通过掺加部分新料以改善其级配,对新加料应取所定料场中有代表性的样品严格按照相关规范和规程进行下列试验:

6.1.5 For milling old materials with poor grading, the grading should be improved by adding some new materials. Representative samples from the designated material yard should be taken for the new materials, and the following tests should be strictly conducted in accordance with relevant specifications and regulations:

(1)颗粒分析;

(1) Particle analysis;

(2)细集料液限和塑性指数;

(2) Liquid limit and plasticity index of fine aggregate;

(3)相对密度;

(3) Relative density;

(4)碎石或砾石的压碎值;

(4) Crushing value of crushed stone or gravel;

(5)有机质含量(必要时做);

(5) Organic matter content (if necessary);

(6)硫酸盐含量(必要时做)。

(6) Sulfate content (if necessary).

6.1.6 有机质含量超过2%或硫酸盐含量超过0.25%的旧路混合料,不得用水泥稳定就地冷再生。

Old road mixtures with organic matter content exceeding 2% or sulfate content exceeding 0.25% shall not be stabilized with cement for on-site cold recycling.

6.1.7 选用初凝时间3h以上和终凝时间较长(宜在6h以上)的普通硅酸盐水泥,不应使用快硬水泥、早强水泥以及已受潮变质的水泥。宜采用 32.5级或42.5级的水泥。

6.1.7 Ordinary Portland cement with an initial setting time of more than 3 hours and a final setting time of more than 6 hours should be selected. Fast hardening cement, early strength cement, and cement that has been affected by moisture and deterioration should not be used. Cement of grade 32.5 or 42.5 should be used.

6.1.8 凡是饮用水(含牲畜饮用水)均可用于水泥稳定就地冷再生施工。水质有疑问时应进行检验。

6.1.8 All drinking water (including livestock drinking water) can be used for on-site cold recycling construction of cement stabilization. When there are doubts about water quality, testing should be conducted.

6.1.9 石灰应为生石灰粉或消石灰,各项技术指标应符合《公路路面基层施工技术规范》(JTJ 034-2000)的有关要求。

6.1.9 Lime should be quicklime powder or hydrated lime, and all technical indicators should comply with the relevant requirements of the "Technical Specification for Construction of Highway Pavement Base" (JTJ 034-2000).

6.2 混合料设计方法

6.2 Mix design method

6.2.1 准备试样并进行配合比设计

6.2.1 Prepare the sample and conduct mix design

1. 将代表试样(旧混合料)完全风干,测定旧混合料完全风干后的含水量。

1. Fully air dry the representative sample (old mixture) and measure the moisture content of the old mixture after complete air drying.

2. 根据旧混合料和新加料的级配确定合成级配,绘制级配曲线,使设计合成级配在相应的级配范围内。设计的合成级配宜接近表中级配范围的中值。当反复调整不能满意时,应更换新加料设计。更换新加料后其合成级配仍不能完全在相应的级配范围内时,如仅为个别筛孔超出,可由终强度的无侧限抗压强度决定此道路是否适合再生,如大部分筛孔超出范围,则此道路不适宜进行再生。

2. Determine the composite gradation based on the gradation of the old mixture and new additives, draw the gradation curve, and ensure that the designed composite gradation is within the corresponding gradation range. The designed composite gradation should be close to the median of the gradation range in the table. When repeated adjustments are unsatisfactory, a new feeding design should be replaced. When the composite gradation cannot be completely within the corresponding gradation range after replacing the new material, if only a few sieve holes exceed it, the unconfined compressive strength of the final strength can determine whether the road is suitable for regeneration. If most sieve holes exceed the range, the road is not suitable for regeneration.

3.将风干后的旧混合料分成以下五个部分:

3. Divide the air dried old mixture into the following five parts:

(1)粒径大于37.5mm的材料;

(1) Materials with a particle size greater than 37.5mm;

(2)粒径在19~37.5mm之间的材料;

(2) Materials with particle sizes between 19 and 37.5mm;

(3)粒径在13.2~19mm之间的材料;

(3) Materials with particle sizes between 13.2-19mm;

(4)粒径在4.75~13.2mm之间的材料;

(4) Materials with particle sizes ranging from 4.75mm to 13.2mm;

(5)小于4.75mm的材料。

(5) Materials smaller than 4.75mm.

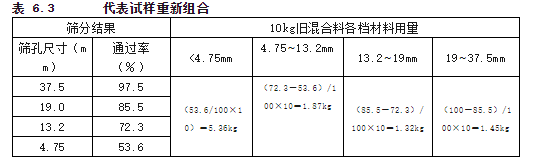

4.将全部通过37.5mm的材料,再按照筛分结果重新组合成代表性试样,并用19~37.5mm之间的材料替代37.5mm以上的材料。配10kg旧混合料计算过程见表6.3。

4. Combine all materials passing through 37.5mm according to the screening results to form a representative sample, and replace materials above 37.5mm with materials between 19-37.5mm. The calculation process for preparing 10kg old mixture is shown in Table 6.3.

表 6.3 代表试样重新组合

Table 6.3 represents the recombination of samples

6.2.2 干密度和含水量的确定

6.2.2 Determination of maximum dry density and optimal moisture content

6.2.2.1 分别按下列五种水泥剂量配制同一种土样、不同水泥剂量的混合料;

6.2.2.1 Prepare a mixture of the same soil sample and different cement dosages according to the following five cement dosages:;

(1)做基层用:4%、4.5%、5%、5.5%,6%,

(1) For grassroots use: 4%, 4.5%, 5%, 5.5%, 6%,

(2)做底基层用:4%、4.5%、5%、5.5%、6%

(2) For use as a base layer: 4%, 4.5%, 5%, 5.5%, 6%

注:在能估计合适剂量的情况下,可以将五个不同剂量缩减到三或四个,如果待稳定材料塑性指数大于12或(和)颗粒较细应适当提高水泥剂量(提高1%~2%)。

Note: If the appropriate dosage can be estimated, five different dosages can be reduced to three or four. If the plasticity index of the material to be stabilized is greater than 12 or (and) the particles are finer, the cement dosage should be appropriately increased (by 1% to 2%).

6.2.2.2 根据设计配合比确定的新旧料比例进行配料,配料时大于37.5mm的材料用19~37.5mm进行替代。

6.2.2.2 According to the design mix proportion, determine the ratio of new and old materials for batching. When batching, materials larger than 37.5mm should be replaced with 19-37.5mm.

6.2.2.3 按公式6.1确定试样的干质量。

6.2.2.3 Determine the dry mass of the sample according to formula 6.1.

(6.1)

(6.1)

式中:

Where:

――试样的干质量,g;

The dry mass of the sample, g;

――试样的风干质量,g;

The air dried quality of the sample, g;

――风干试样的含水量,%。

Moisture content of air dried samples,%.

6.2.2.4 按公式6.2确定稳定剂的用量。

6.2.2.4 Determine the dosage of stabilizer according to formula 6.2.

(6.2)

(6.2)

式中:

Where:

――水泥或石灰用量,g;

The amount of cement or lime used, g;

――水泥或石灰的百分比,%;

- Percentage of cement or lime,%;

――试样的干质量,g。

The dry mass of the sample, g。

6.2.2.5 按照《公路工程无机结合料稳定材料试验规程》(JTJ 057-94)T0804-94方法确定混合料的干密度和含水量。确定各种混合料的含水量和干(压实)密度,少应做三个不同水泥剂量混合料的击实试验,即小剂量、中间剂量和剂量。其他两个剂量混合料的含水量和干密度用内插法确定。

6.2.2.5 Determine the maximum dry density and optimal moisture content of the mixture according to the T0804-94 method in the "Test Code for Inorganic Bonding Materials in Highway Engineering" (JTJ 057-94). To determine the optimal moisture content and maximum dry (compacted) density of various mixtures, at least three compaction tests should be conducted for mixtures with different cement dosages, namely minimum dosage, intermediate dosage, and maximum dosage. The optimal moisture content and maximum dry density of the other two dosage mixtures were determined using interpolation.

6.2.3 稳定材料的准备

6.2.3 Preparation of Stable Materials

6.2.3.1 根据公式6.1计算试样干质量。

6.2.3.1 Calculate the dry mass of the sample according to formula 6.1.

6.2.3.2根据公式6.2计算稳定剂用量。

6.2.3.2 Calculate the stabilizer dosage according to formula 6.2.

6.2.3.3按公式6.3确定加水百分比,并按式6.4确定需要加水的质量。

6.2.3.3 Determine the percentage of water added according to formula 6.3, and determine the required amount of water to be added according to formula 6.4.

(6.3)

(6.3)

(6.4)

(6.4)

式中:

Where:

――试样的加水百分比,%;

-- Percentage of water added to the sample,%;

――试样的含水量,%;

The optimal moisture content of the sample,%;

――风干试验的含水量,%;

Moisture content of air drying test,%;

――加水质量,g;

-- Quality of water added, g;

――试样干重,g;

-- Dry weight of the sample, g;

――稳定剂添加量,g。

-- stabilizer addition amount, g。

6.2.4 成型试件(静压成型)

6.2.4 Forming test piece (static pressure forming)

6.2.4.1 按规定压实度分别计算不同水泥剂量的试件应有的干密度。

6.2.4.1 Calculate the dry density of specimens with different cement dosages according to the prescribed compaction degree.

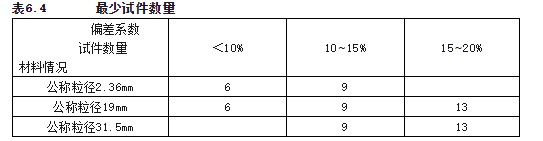

6.2.4.2 根据含水量和计算的干密度制备试件。进行强度试验时,作为平行试验的少试件数量应不小于表6.4的规定。如试验结果的偏差系数大于表中规定的值,则应重做试验,并找出原因,加以解决。如不能降低偏差系数,则应增加试件数量。

6.2.4.2 Prepare specimens based on the optimal moisture content and calculated dry density. When conducting strength tests, the minimum number of specimens used as parallel tests should not be less than the provisions in Table 6.4. If the deviation coefficient of the test results is greater than the value specified in the table, the test should be redone, and the cause should be identified and resolved. If the deviation coefficient cannot be reduced, the number of specimens should be increased.

6.2.4.3 试件在温度20±2℃、湿度大于95%的养护室内养生6d,浸水24h后,按《公路工程无机结合料稳定材料试验规程》(JTJ057)进行无侧限抗压强度试验。

6.2.4.3 The specimen shall be cured in a curing room with a temperature of 20 ± 2 ℃ and humidity greater than 95% for 6 days. After being immersed in water for 24 hours, an unconfined compressive strength test shall be conducted in accordance with the "Test Specification for Inorganic Bonding Materials in Highway Engineering" (JTJ057).

6.2.5 确定稳定剂的用量

6.2.5 Determine the optimal dosage of stabilizer

6.2.5.1 计算无侧限抗压强度试验结果的平均值和偏差系数。

6.2.5.1 Calculate the average value and deviation coefficient of the unconfined compressive strength test results.

6.2.5.2 根据要求的强度标准,选定合适的水泥剂量,此剂量试件室内试验结果的平均抗压强度应符合公式6.5的要求:

6.2.5.2 According to the required strength standards, select the appropriate cement dosage, and the average compressive strength of the indoor test results of this dosage specimen should meet the requirements of formula 6.5:

≥Rd/(1-ZaCv) (6.5)

≥Rd/(1-ZaCv) (6.5)

式中:

Where:

Rd——设计抗压强度;

Rd - Design compressive strength;

Cv——试验结果的偏差系数(以小数计);

Cv - Deviation coefficient of test results (in decimal units);

Za——标准正态分布表中随保证率(或置信度a)而变的系数,取保证为率90%,即Za=1.282。

Za - the coefficient in the standard normal distribution table that varies with the guarantee rate (or confidence level a), with a guarantee rate of 90%, i.e. Za=1.282.

6.2.5.3 工地人工撒布水泥,实际采用的水泥剂量应比室内试验确定的剂量多0.5~1.0%;采用水泥稀浆车,实际采用的水泥剂量应比室内试验确定的剂量多0~0.5%。

6.2.5.3 When manually spreading cement on construction sites, the actual cement dosage used should be 0.5-1.0% higher than the dosage determined by indoor tests; When using a cement slurry truck, the actual cement dosage used should be 0-0.5% higher than the dosage determined by indoor tests.

6.2.5.4 水泥的小剂量应不低于4%。

6.2.5.4 The minimum dosage of cement should not be less than 4%.

7 铺筑试验段

7 Paving test section

7.1 一般规定

7.1 General Provisions

7.1.1 每一工程开工前应铺筑试验段。

7.1.1 Before the commencement of each project, a test section should be laid.

7.1.2 根据道路结构形式和损坏状况选取试验段,使试验段具有代表性。

7.1.2 Select the test section based on the road structure and damage condition to make it representative.

7.1.3 试验段的长度不应短于200m。

The length of the test section should not be less than 200m.

7.1.4 再生时应严格控制再生深度,如遇问题应及时解决。

7.1.4 During regeneration, the regeneration depth should be strictly controlled, and any problems should be promptly resolved.

7.1.5 通过试验段的铺筑应获得以下资料:

7.1.5 The following information should be obtained through the paving of the test section:

(1)再生材料的级配。检验再生后的材料,与试验室进行配合比设计时的级配进行对比,看其是否在允许的波动范围内。

(1) Grading of recycled materials. Inspect the regenerated material and compare it with the gradation during the mix design in the laboratory to see if it is within the allowable fluctuation range.

(2)确定再生机的行进速度和转子速度。

(2) Determine the travel speed and rotor speed of the regeneration machine.

(3)确定压实工艺。

(3) Determine the compaction process.

(4)了解旧路的膨胀性。

(4) Understand the expansibility of old roads.

7.1.6 通过铺筑试验段,操作人员、监理人员以及管理人员应了解再生材料的有关特性。

7.1.6 Through the paving test section, operators, supervisors, and managers should have a comprehensive understanding of the relevant characteristics of recycled materials.

7.2 试验段施工

7.2 Experimental section construction

7.2.1 按要求选定试验段。

7.2.1 Select the test section as required.

7.2.2 根据经验和所用再生机械的特点,制定3~5种不同的再生机行进速度和转子速度的组合方案,按再生深度对旧路进行铣刨,取铣刨后具有代表性的材料送往试验室进行筛分,选择级配接近理想级配的方案作为施工时再生机行进速度和转子速度的方案。

7.2.2 Based on experience and the characteristics of the recycling machinery used, develop 3-5 different combinations of recycling machine travel speed and rotor speed, mill the old road according to the recycling depth, take representative materials after milling and send them to the laboratory for screening, and select the scheme with the closest gradation to the ideal gradation as the scheme for recycling machine travel speed and rotor speed during construction.

7.2.3 按照7.2.2确定的再生机行进速度和转子速度,根据再生深度对旧路铣刨,取铣刨后具有代表性的材料样品送往试验室进行室内配合比设计。

7.2.3 According to the determined speed of the regeneration machine and rotor speed in 7.2.2, the old road is milled according to the regeneration depth. Representative material samples after milling are taken and sent to the laboratory for indoor mix design.

7.2.4 按照室内试验结果,在旧路上摊铺新加料,但不添加稳定剂,按7.2.2确定的方案进行铣刨,取铣刨后具有代表性的材料样品送往试验室进行筛分,如果筛分后的级配与室内设计级配超过工地允许波动范围,应调整再生机速度和转子速度,使铣刨后的级配与室内设计级配相比波动在允许范围内。

7.2.4 According to the indoor test results, new materials shall be spread on the old road without adding stabilizers. Milling shall be carried out according to the scheme determined in 7.2.2. Representative material samples after milling shall be taken and sent to the laboratory for screening. If the screened gradation exceeds the allowable fluctuation range of the construction site compared to the indoor design gradation, the speed of the regeneration machine and rotor shall be adjusted to ensure that the milled gradation fluctuates within the allowable range compared to the indoor design gradation.

7.2.5 按照本指南进行严格施工,采用1-3种压实方案进行施工(包括压路机吨位、碾压顺序、遍数等),以确定为合理的碾压方案。

7.2.5 Strictly carry out construction according to this guide, using 1-3 compaction schemes (including roller tonnage, rolling sequence, number of passes, etc.) to determine the most reasonable compaction scheme.

7.2.6 取再生机后经铣刨、拌和的混合料,送往试验室,测定再生混合料的含水量、水泥剂量,并按《公路工程无机结合料稳定材料试验规程》(JTJ 57-94)要求成型试件,测定其7d无侧限抗压强度。

7.2.6 Take the mixture after milling and mixing from the recycling machine, send it to the laboratory, measure the moisture content and cement dosage of the recycled mixture, and form the test piece according to the requirements of the "Test Code for Stable Materials of Inorganic Bonding Materials in Highway Engineering" (JTJ 57-94) to determine its 7-day unconfined compressive strength.

7.2.7 对试验段的弯沉、压实度、平整度、厚度、宽度进行检测,其应满足现行相关规范和设计要求。

7.2.7 The deflection, compaction degree, flatness, thickness, and width of the test section shall be tested to meet the current relevant specifications and design requirements.

7.2.8 根据试验段的结果终确定再生混合料的级配、施工时采用的再生机行进速度、转子速度及再生结构层压实工艺。

7.2.8 Based on the results of the test section, determine the gradation of the recycled mixture, the speed of the recycling machine used during construction, the rotor speed, and the compaction process of the recycled structural layer.

8 施工工艺

8 Construction Techniques

8.1 水泥稳定就地冷再生的工艺流程宜按图8.1的顺序进行

The process flow of on-site cold regeneration for cement stabilization should be carried out in the order shown in Figure 8.1

8.2 整个施工及养护过程中,应对再生路段(路幅)封闭交通,各路口设置警示牌,提醒司机及行人。

During the entire construction and maintenance process, the regenerated road section (road width) should be closed to traffic, and warning signs should be set up at each intersection to remind drivers and pedestrians.

图8.1 水泥稳定就地冷再生工艺流程

Figure 8.1 Cement stabilization on-site cold recycling process flow

8.3 施工放样

8.3 Construction layout

8.3.1 在再生施工之前,应在道路的两侧放置一系列的标桩(杆)作为基线,用来恢复道路的中心线。

Before the regeneration construction, a series of stakes (poles) should be placed on both sides of the road as baselines to restore the centerline of the road.

8.3.2 标桩(杆)的间距,曲线距离不应超过20米,直线距离不应超过40米。

8.3.2 The spacing between stakes (poles) should not exceed 20 meters for curved lines and 40 meters for straight lines.

8.4 准备原道路

8.4 Prepare the original road

8.4.1 原道路表面(包括不需要再生的相临行车道和路肩)的石块、垃圾、杂草等杂物和积水,并清理边线。

8.4.1 Remove stones, garbage, weeds, and other debris and standing water from the original road surface (including adjacent lanes and shoulders that do not require regeneration), and clean the edges.

8.4.2 再生路段上存在的井盖等类似结构物。

8.4.2 Remove manhole covers and similar structures from the regeneration section.

8.4.3 对原路的翻浆、车辙、沉陷、波浪、坑槽等病害进行处理,使原路基本平整。

8.4.3 Treat the damages such as mud heave, ruts, subsidence, waves, potholes, etc. on the original road to make it basically flat.

8.5 准备新加料

8.5 Prepare new ingredients

8.5.1 计算材料用量:

8.5.1 Calculation of Material Consumption:

(1)根据原道路再生深度内的平均密度,计算每平米新料的添加量。

(1) Calculate the amount of new material added per square meter based on the average density within the original road regeneration depth.

(2)根据每车料的质量或体积,计算每车料的堆放距离。

(2) Calculate the stacking distance of each vehicle based on its mass or volume.

(3)人工摆放和撒布水泥,应根据水泥剂量,计算每一水泥稳定层需要的水泥用量,并确定水泥摆放的纵横间距。使用水泥稀浆车,应计算水泥浆的喷入量。

(3) When manually placing and spreading cement, the amount of cement required for each square meter of cement stabilization layer should be calculated based on the cement dosage, and the vertical and horizontal spacing of cement placement should be determined. When using a cement slurry truck, the amount of cement slurry sprayed should be calculated.

8.5.2 新加料装车时,应控制每车料的数量基本相等。

When loading new materials, the quantity of each vehicle should be controlled to be basically equal.

8.5.3 在同一料场供料的路段内,由远到近将料按上述计算距离卸置于原路面的中间。卸料距离应严格掌握,避免有的路段料不够或过多。

8.5.3 In the section of the same material yard where materials are supplied, the materials shall be unloaded in the middle of the original road surface according to the calculated distance from far to near. The unloading distance should be strictly controlled to avoid insufficient or excessive material on some road sections.

8.5.4 将新加料均匀地撒布在旧路面上,并检查新加料撒布是否均匀。

8.5.4 Spread the new material evenly on the old road surface and check if the new material is evenly distributed.

8.6 冷再生机组就位

8.6 Cold regeneration unit in place

8.6.1 使用推杆连接再生机组,并连接所有与再生机相连的管道。

8.6.1 Use push rods to connect the regeneration unit and connect all pipelines connected to the regeneration machine.

8.6.2 检查再生机操作人员是否已将所有与稳定剂添加量有关的数据输入计算机。

8.6.2 Check if the operator of the regeneration machine has entered all data related to the amount of stabilizer added into the computer.

8.6.3 人工摆放和撒布水泥。使用水泥稀浆车,应检查水泥稀浆车内的水泥和水是否充足。

8.6.3 Manual placement and spreading of cement. When using a cement slurry truck, it is necessary to check whether the cement and water inside the truck are sufficient.

8.6.4 排除系统中的所有空气并确保所有阀门均处于全开度位置。

8.6.4 Remove all air from the system and ensure that all valves are in the fully open position.

8.6.5 检查再生路段内的导向标志,确保导向标志明确。

8.6.5 Check the directional signs within the regeneration section to ensure that they are clear.

8.6.6 对再生施工中所需要的其它机械设备进行的检查。

8.6.6 Conduct a comprehensive inspection of other mechanical equipment required for regeneration construction.

8.7 摆放和撒布水泥(使用水泥稀浆车时无此步骤)

8.7 Placing and spreading cement (this step is not required when using a cement slurry truck)

8.7.1 按本章第8.5.2条计算出的每袋水泥的纵横间距,在旧路上做好安放标记。

8.7.1 Calculate the longitudinal and transverse spacing of each bag of cement according to Article 8.5.2 of this chapter, and mark the placement on the old road.

8.7.2 应将水泥当日直接送到撒布路段,卸在做标记的地点,并检查有无遗漏和多余。

8.7.2 The cement should be directly delivered to the spreading section on the same day, unloaded at the marked location, and checked for omissions and excess.

8.7.3 将水泥均匀摊开,并注意使每袋水泥的撒布面积相等。水泥撒布完后,表面应没有空白位置,也没有水泥过分集中的地点。

8.7.3 Spread the cement evenly and ensure that the spreading area of each bag of cement is equal. After the cement is spread, there should be no blank spaces on the surface or areas where cement is excessively concentrated.

8.8 冷再生机铣刨与拌和

8.8 Cold recycling machine milling and mixing

8.8.1 冷再生机推动稀浆车或水车在原路面上行进。

8.8.1 The cold regeneration machine drives the slurry truck or water truck to travel on the original road surface.

8.8.2 冷再生机行进速度应根据路面损坏状况和再生深度进行调整,一般为6m/min~12m/min,使得铣刨后料的级配波动范围不大。网裂严重地段应降低再生机组行进速度,提高铣刨转子转速。

8.8.2 The traveling speed of the cold recycling machine should be adjusted according to the damage condition of the road surface and the depth of regeneration, generally ranging from 6m/min to 12m/min, so that the gradation fluctuation range of the milled material is not large. In areas with severe mesh cracking, the speed of the regeneration unit should be reduced and the milling rotor speed should be increased.

8.8.3 再生机后应有专人跟随,随时检查再生深度、水泥含量和含水量,并配合再生机操作员进行调整。

8.8.3 After the regeneration machine, there should be a dedicated person to follow and check the regeneration depth, cement content, and moisture content at any time, and cooperate with the regeneration machine operator to make adjustments.

8.8.4 施工中再生深度的检查以相邻已经再生或原路面为标准,用钢纤刺入土中,测量其刺入深度,看其深度是否合格。

8.8.4 The inspection of the depth of regeneration during construction shall be based on the adjacent regenerated or original road surface. Steel fibers shall be used to pierce into the soil, and the penetration depth shall be measured to see if it is qualified.

8.8.5 应在作业面边缘固定导向线以帮助操作者。

8.8.5 Guide lines should be fixed at the edge of the work surface to assist the operator.

8.8.6 若进行多刀施工时,应时刻注意搭接的宽度,保证搭接宽度。

8.8.6 When carrying out multi blade construction, attention should be paid to the width of the overlap at all times to ensure the overlap width.

8.8.7 再生机后宜安排4~5人处理边线和清理混合料中的杂质以及每刀起始位置的余料,以防止影响纵向接缝、横向接缝、平整度和再生材料的密实性。

8.8.7 After regeneration, it is advisable to arrange 4-5 people to handle the edges and clean up impurities in the mixture, as well as the remaining material at the starting position of each knife, to prevent affecting the longitudinal joints, transverse joints, flatness, and compactness of recycled materials.

8.8.8 带有熨平板的再生机,应经常检查熨平板后混合料的厚度。

8.8.8 Regeneration machines with ironing plates should regularly check the thickness of the mixture after ironing.

8.8.9 在施工过程中,对混合料的级配、再生深度、水(或水泥稀浆)的喷入量有任何疑问时,应停止施工,等问题解决后再继续施工。

8.8.9 During the construction process, if there are any questions about the grading, regeneration depth, or water (or cement slurry) injection amount of the mixture, the construction should be stopped and the problem should be resolved before continuing.

8.8.10 每次再生的长度以保证后续作业能正常进行为宜,应认真组织施工,使再生的长度尽可能长些,以减少横向接缝。一次(不停机)再生的长度一般为150m~250m。

8.8.10 The length of each regeneration should be ensured to ensure the normal progress of subsequent operations. Construction should be carefully organized to make the regeneration length as long as possible to reduce horizontal joints. The length of a single (non-stop) regeneration is generally between 150m and 250m.

8.8.11 每段再生结束后,应检查铣刨毂的刀架、刀头,发现损坏立即更换。

8.8.11 After each regeneration is completed, the tool holder and cutting head of the milling hub should be inspected, and any damage should be replaced immediately.

8.9. 碾压整形

8.9. Rolling and shaping

8.9.1 根据路宽、压路机的轮宽和轮距的不同,制订碾压方案,应使各部分碾压到的次数尽量相同,路面的两侧应多压2~3遍。

8.9.1 According to the differences in road width, roller width, and wheelbase, a rolling plan should be formulated to ensure that each part is rolled as frequently as possible, and the two sides of the road surface should be rolled 2-3 times more.

8.9.2 使用轮胎式再生机时,在整形之前,必须压实轮迹间松散的材料。

When using a tire type regeneration machine, the loose material between the wheel tracks must be compacted before shaping.

8.9.3 在再生机后应紧跟一台钢轮振动压路机或凸块式振动压路机进行初压,采用高幅低频进行压实,压实遍数应足以保证再生层底部2/3厚度范围内的压实度达到规定要求。钢轮压路机的工作速度不得超过3km/h。

8.9.3 After the regeneration machine, a steel wheel vibration roller or a convex block vibration roller should be followed for initial compaction, using high amplitude and low frequency compaction. The number of compaction passes should be sufficient to ensure that the compaction degree within 2/3 of the thickness range of the bottom of the regeneration layer meets the specified requirements. The working speed of the steel wheel roller shall not exceed 3km/h.

8.9.4 在初压完成后,应立即用平地机整形。在直线段,平地机由两侧向路中心进行刮平;在平曲线段,平地机由内侧向外侧进行刮平。必要时,再返回刮一遍。

8.9.4 After the initial pressing is completed, the grader should be used immediately for shaping. In the straight section, the grader flattens from both sides towards the center of the road; On the flat curve section, the grader flattens from the inside to the outside. If necessary, go back and scrape again.

8.9.5 对于局部低洼处,应用齿耙将其表层5cm以上耙松,并用新拌的混合料进行找平。

8.9.5 For locally low-lying areas, use a toothed rake to loosen the surface layer by more than 5cm and level it with freshly mixed material.

8.9.6 整形时应将高处料直接刮出路外,不应形成薄层贴补现象。

During plastic surgery, the high material should be directly scraped out of the road without forming a thin layer of patching.

8.9.7 在整形过程中,严禁任何车辆通行,并保持无明显的粗细集料离析现象。

8.9.7 During the plastic surgery process, it is strictly prohibited for any vehicle to pass through and there should be no obvious separation of coarse and fine aggregates.

8.9.8 整形后,当混合料的含水量为含水量时,应立即用光轮压路机先以高幅低频振动模式后以低幅高频模式进行压实。直线和不设超高的平曲线段,由路肩向路中心碾时,应重叠1/2轮宽,后轮必须超过两段的接缝处,后轮压完路面全宽时,即为一遍。一般需碾压6~8遍。压路机的碾压速度,头两遍以采用1.5~1.7km/h为宜,以后宜采用2.0~2.5km/h。

After shaping, when the moisture content of the mixture reaches the optimal moisture content, a smooth wheel roller should be used immediately to compact it in high amplitude low-frequency vibration mode and then in low amplitude high-frequency mode. When rolling straight lines and flat curved sections without superelevation from the shoulder to the center of the road, they should overlap by 1/2 of the wheel width, and the rear wheel must exceed the joint between the two sections. When the rear wheel presses the full width of the road surface, it is considered as one pass. Generally, it needs to be rolled 6-8 times. The rolling speed of the road roller should be 1.5-1.7km/h for the first two passes, and 2.0-2.5km/h for subsequent passes.

8.9.9 严禁压路机在已完成的或正在碾压的路段上调头或急刹车,应保证再生层表面不受破坏。

8.9.9 It is strictly prohibited for the roller to turn around or brake abruptly on the completed or rolling road section, and the surface of the regeneration layer should be ensured not to be damaged.

8.9.10 碾压过程中,再生层的表面应始终保持湿润,如水分蒸发过快,应及时补撒少量的水,但严禁大量洒水碾压。

During the rolling process, the surface of the recycled layer should always be kept moist. If the water evaporates too quickly, a small amount of water should be sprinkled in a timely manner, but it is strictly prohibited to sprinkle a large amount of water for rolling.

8.9.11 碾压过程中,如有“弹簧”、松散、起皮等现象,应及时翻开重新拌和(加适量的水泥)或用其他方法处理,使其达到质量要求。

During the rolling process, if there are "springs", looseness, peeling and other phenomena, they should be promptly opened and re mixed (with an appropriate amount of cement) or treated with other methods to meet the quality requirements.

8.9.12 经过拌和、整形的水泥稳定就地冷再生层,宜在水泥初凝前并应在试验确定的延迟时间内完成碾压,并达到要求的密实度,同时没有明显的轮迹。

8.9.12 After mixing and shaping, the cement stabilized in-situ cold recycling layer should be compacted before the initial setting of the cement and within the delay time determined by the test, and achieve the required density without obvious wheel marks.

8.9.13 在碾压结束之前,用平地机再终平一次,使其纵向顺适,路拱和超高符合设计要求。终平应仔细进行,必须将局部高出部分刮除并扫出路外;对于局部低洼之处,不再进行找补,可留待铺筑沥青面层时处理。

Before the rolling is completed, use a grader to level it again to make it longitudinally smooth and the road arch and superelevation meet the design requirements. The final leveling should be carried out carefully, and the locally raised parts must be scraped off and swept out of the road; For locally low-lying areas, no further repairs will be made and can be left to be dealt with when laying the asphalt surface layer.

8.10 接缝和调头处的处理

8.10 Treatment of seams and turning points

8.10.1 纵向接缝的处理

8.10.1 Treatment of longitudinal seams

(1)道路宽度小于7m,纵向重叠较多时,不宜半幅施工,应考虑全幅施工,以减少重叠量,提高施工效率。

(1) When the road width is less than 7m and there is a lot of longitudinal overlap, it is not suitable to carry out half width construction. Full width construction should be considered to reduce the amount of overlap and improve construction efficiency.

(2)一般重叠宽度为50-150mm。

(2) The general overlap width is 50-150mm.

(3)路面材料越厚,材料粒度越粗,重叠量越大。

(3) The thicker the pavement material, the coarser the particle size of the material, and the greater the overlap.

(4)相邻两次作业间隔12h以上时,重叠量应增加。

(4) When the interval between two adjacent assignments is more than 12 hours, the overlap should be increased.

(5)在纵向接缝上,根据已建再生层的完成时间,改变水泥稀浆(或水)的喷入量。

(5) On the longitudinal joint, adjust the amount of cement slurry (or water) sprayed according to the completion time of the existing regeneration layer.

(6)纵向接缝的位置应尽量避开慢行、重型车辆的轮迹。

(6) The position of longitudinal joints should avoid the wheel tracks of slow-moving and heavy vehicles as much as possible.

8.10.2 横向接缝的处理

8.10.2 Treatment of transverse joints

(1) 应对所形成的横向接缝认真处理,施工中应尽量减少停机现象。

(1) Handle the horizontal joints carefully and minimize downtime during construction.

(2) 停机超过水泥初凝时间,再生机再次施工时,必须将整个再生机后退再生过的路段1.5m的距离,并重新撒布水泥。

(2) When the shutdown exceeds the initial setting time of the cement and the regeneration machine is restarted, the entire regeneration machine must be moved back to a distance of 1.5 meters from the regenerated section and the cement must be re spread.

8.10.3 调头处的处理

8.10.3 Handling of Turning Points

如机械必须到已压成的水泥稳定就地冷再生层上调头,应采取措施保护调头作业段。一般可在准备用于调头的约8~10m长的稳定土上,先覆盖一张厚塑料布或油毡纸,然后铺上约10cm厚的土、砂或砂砾。

If the machinery must be turned on the stabilized on-site cold regeneration layer of the already pressed cement, measures should be taken to protect the turning operation section. Generally, on a stable soil of about 8-10 meters long that is prepared for turning, a thick plastic cloth or oil felt paper can be covered first, and then about 10 cm thick soil, sand or gravel can be laid on top.

9 养生及交通管制

9 Health Preservation and Traffic Control

9.1 水泥稳定就地冷再生层宜养生7d后铺筑上层混合料。如果上层混合料仍为无机结合料稳定类材料时,宜在下层表面撒少量水泥或水泥浆。

9.1 The cement stabilized in-situ cold regeneration layer should be cured for 7 days before laying the upper layer mixture. If the upper mixture is still a stable inorganic binder material, it is advisable to sprinkle a small amount of cement or cement slurry on the surface of the lower layer.

9.2 每一段碾压完成并经压实度检查合格后,应立即开始养生。

After each section of compaction is completed and passes the compaction degree inspection, the curing process should begin immediately.

9.3 宜采用覆盖(吸水土工布等)进行养生。养生结束后,必须将覆盖物干净。

9.3 It is advisable to use coverings (such as absorbent geotextiles) for health preservation. After the health preservation is completed, the covering must be cleaned thoroughly.

9.4 对于基层,可采用沥青乳液进行养生。

9.4 For the base course, asphalt lotion can be used for curing.

9.5 无上述条件时,也可用洒水车经常洒水进行养生。每天洒水的次数应视气候而定。整个养生期间应始终保持稳定土层表面潮湿,应注意表层情况,必要时,用两轮压路机压实。

When the above conditions are not met, a sprinkler truck can also be used to regularly sprinkle water for health preservation. The frequency of watering per day should depend on the climate. Throughout the entire health preservation period, the surface of the soil layer should be kept stable and moist. Attention should be paid to the surface condition, and if necessary, a two wheeled roller should be used to compact it.

9.6 基层的养生期不宜少于7d。

The health maintenance period at the grassroots level should not be less than 7 days.

9.7 在养生期间未采用覆盖措施的水泥稳定就地冷再生层上,除洒水车外,应封闭交通。不能封闭交通时,应限制重车通行,其他车辆的车速不应超过30km/h。

During the health preservation period, if no covering measures are taken on the cement stabilized in-situ cold regeneration layer, traffic should be closed except for the sprinkler truck. When traffic cannot be closed, the passage of heavy vehicles should be restricted, and the speed of other vehicles should not exceed 30km/h.

10 质量控制

10 Quality Control

10.1 材料应满足混合料组成设计中相关要求。

10.1 The material should meet the relevant requirements in the mix composition design.

10.2 严格按照施工工艺要求认真施工。

10.2 Strictly follow the construction process requirements and construct diligently.

10.3 如发生未预料的特殊情况,可能会影响工程质量的应立即停工,待问题解决后再继续施工。

10.3 In case of unforeseen special circumstances that may affect the quality of the project, the work should be immediately suspended until the problem is resolved before resuming construction.

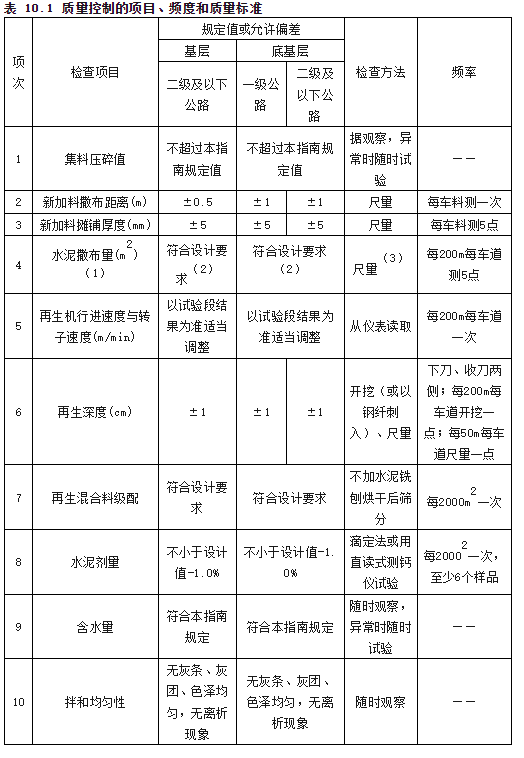

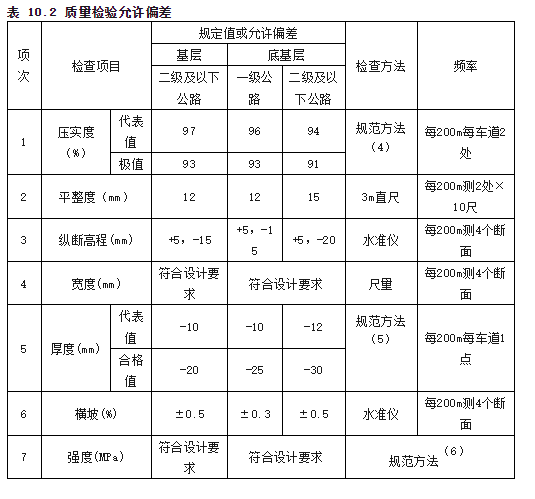

10.4 质量控制标准应符合表10.1要求,评定标准应符合表10.2要求,表中允许偏差均指与设计值之差。

10.4 The quality control standards shall comply with the requirements of Table 10.1, and the evaluation criteria shall comply with the requirements of Table 10.2. The allowable deviations in the table refer to the difference from the design values.

10.5 包括再生层在内的其他检测项目应符合《公路工程质量检验评定标准》(JTG F80/1-2004)中相关规定。

10.5 Other testing items, including the regeneration layer, shall comply with the relevant provisions of the "Quality Inspection and Evaluation Standards for Highway Engineering" (JTG F80/1-2004).

10.6 碾压合格后应立即覆盖或洒水养生,养生期应符合指南要求。

10.6 After passing the compaction, it should be immediately covered or watered for curing, and the curing period should meet the requirements of the guidelines.

本文由 冷再生机租赁 友情奉献.更多有关的知识请点击 http://www.tclqgc.com/ 真诚的态度.为您提供为的服务.更多有关的知识我们将会陆续向大家奉献.敬请期待.

This article is a friendly contribution from Cold Recycling Machine Rental For more related knowledge, please click http://www.tclqgc.com/ Sincere attitude To provide you with comprehensive services We will gradually contribute more relevant knowledge to everyone Stay tuned

阅读/ Recommended reading

- 冷再生机租赁全解析:如何通过无需加热的一次成型技术实现道路修复 2026-02-26

- 冷再生机租赁全解析:如何通过的就地再生技术实现道路快速修复 2026-02-25

- 冷再生机租赁全解析:如何通过的就地再生技术降低道路养护成本 2026-02-25

- 冷再生机租赁:道路冷再生时粒径过过大时的处理办法 2026-02-23

冷再生机租赁全解析:如何通过服务选择与操作浅层就地冷再生设备 Full Analysis of Cold Recycling Machine Rental: How t...